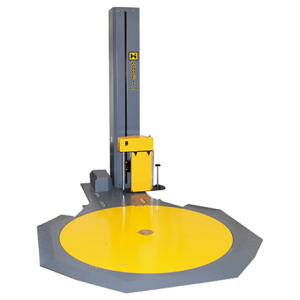

Introducing the FPS-400H High Profile Pallet Wrapping Machine: Unparalleled Durability and Efficiency for High-Cycle Clients

If you’re in need of a reliable and efficient pallet wrapping solution for high-volume operations, look no further than our FPS-400H High Profile Pallet Wrapping Machine. Designed specifically for high-cycle clients, this machine offers numerous advantages, including reduced maintenance requirements and exceptional durability.

The FPS-400H is the high-profile version of the FPS-400, designed to cater to the unique needs of high-volume applications. With considerably fewer parts to service and maintain, this machine ensures maximum uptime and productivity. By streamlining the maintenance process, you can focus more on your core operations and minimize unnecessary downtime.

One of the standout features of the FPS-400H is its elevated height from the ground. By sitting much higher off the ground, all sensitive parts are safely stowed away under the turntable, away from the risk of potential forklift damage. This design not only ensures the longevity of the machine but also enhances the safety and reliability of your pallet wrapping process.

It’s important to note that due to its elevated height, the FPS-400H does not offer a ramp option. This model is specifically designed for loading by forklift or overhead crane. This configuration ensures efficient loading and unloading processes, maximizing productivity and minimizing handling time.

For high-cycle clients who prioritize uptime and reduced service calls, the FPS-400H is the perfect solution. The significant savings in downtime and service costs make this machine a worthwhile investment. By minimizing the need for maintenance and service, you can allocate more time and resources to your core business activities.

Investing in the FPS-400H High Profile Pallet Wrapping Machine allows you to experience unparalleled durability and efficiency in your high-volume packaging operations. Its robust construction and innovative design ensure long-term reliability, allowing you to achieve consistent and secure pallet wraps.

Choose the FPS-400H for your high-cycle requirements, and enjoy the benefits of enhanced productivity, reduced maintenance, and increased operational efficiency. Contact us today to discuss your needs and discover how our advanced pallet wrapping machine can revolutionize your packaging workflow.

CONTROL FEATURES

- 32 I/O PLC (Programmable Logic Control) by DELTA

- Full color 7” touchscreen display by DELTA

(providing function control viewing)

- DELTA 1 HP AC VFD’s

- Variable Turntable Speed 0-15 RPM

- Variable Film Carriage Speed Up/Down Control

- Separate Top/Bottom Wrap Selectors 1-9

- Separate Film Height Selector 1-9″

- Flush Mounted Control Panel (built into the tower)

- Cycle Counter

- Manual Carriage Raise/Lower Control

- Turntable Jog with Auto Home Alignment

- Large Emergency push button power On/Off

Switch with the indicator light

- Start Cycle Push Button

- 3 different onboard wrap programs

- All circuits are protected by fuses (easy access)

THE FPS-400H HAS A BUILT-IN PATENTED END-OF-CYCLE FILM CUTTER AT NO EXTRA COST A UNIQUE TOTAL MECHANICAL DEVICE THAT WORKS EVERY TIME AND IS BUILT TO LAST WHICH ELIMINATES THE NEED FOR KNIVES PLUS IT’S ONE LESS FUNCTION THE OPERATOR IS REQUIRED TO PERFORM.

FILM DELIVERY SYSTEM

- HURRICANE THREAD 20” prestretch film delivery system

- 200% factory set stretch (50-250% available upon request)

- Easy thread film carriage

- Electronic film force control on the panel

- Adjustable mechanical force to load

- Linear analog proximity sensor film feed speed control

- 3/4HP AC MOTOR & DELTA 1 HP VFD

- Triple beam auto height eye

CARRIAGE LIFT

- UHMW supports providing effortless

movement and maximum stability (Qty4)

- Heavy duty ANSI #50 chain carriage lift

- 3/4HP AC MOTOR & DELTA 1 HP VFD / 60:1 GEARBOX

- The carriage chain is fully guarded

TURNTABLE DRIVE

- 0–15 RPM Table Speed

- 3/4HP AC MOTOR & DELTA 1 HP VFD / 20:1 GEARBOX

- Adjustable electronic soft start/stop

- Positive home position alignment

- Safety E-Stop button

- 4 heavy-duty swivel casters

FPS 400H SPECIFICATIONS:

PRODUCTION SPEED:

- 1-40 LPH*

LOAD SIZE

- 55″L x 55″W x 82″H (80″ Diagonal)

WEIGHT CAPACITY

- 5000LBS

STRUCTURAL

- WELDED STEEL CONSTRUCTION

- 4 HEAVY-DUTY SWIVEL CASTERS

TURNTABLE DRIVE

- 3/4HP AC MOTOR & DELTA 1 HP VFD

- 20:1 GEARBOX

TURNTABLE SPEED

- 0-15RPM

CARRIAGE DRIVE

- 3/4HP AC MOTOR & DELTA 1 HP VFD

- #50 ANSI CHAIN

FILM DELIVERY

- HURRICANE PRESTRETCH CARRIAGE

FILM ROLL

- 20″ MACHINE FILM, 3″ CORE

POWER REQUIREMENTS

- 115VAC, 15A, 60Hz- PLUG AND PLAY

ONBOARD PROGRAMS

- STANDARD WRAP CYCLE

- STD W/TOP COVER PAUSE

- WRAP UPWARDS ONLY

OPTIONS

- HEIGHT/BASE EXTENSION

- INTEGRATED SCALE PACKAGE

*Loads Per Hour- This may vary depending on load sizes, loading/unloading speeds, and the number of wraps or wrapping pauses on load.