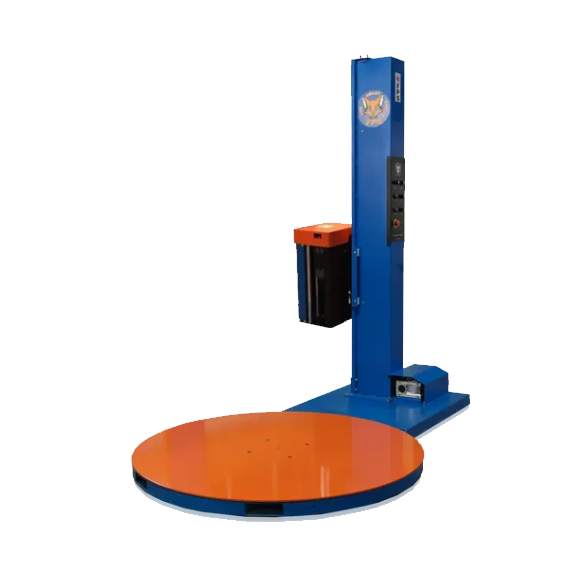

Introducing our Advanced Pallet Wrapping Machine with Built-in PLC HMI Display

Are you in need of a pallet wrapping solution that offers advanced functionality and versatility? Look no further than our cutting-edge pallet wrapping machine with a built-in PLC HMI (Human-Machine Interface) display. This state-of-the-art machine is designed to streamline your packaging process by providing a wide range of customizable options to meet your unique requirements.

Our pallet wrapping machine with a built-in PLC HMI display is your key to achieving efficient and consistent wrapping results. With this advanced feature, you gain full control over the wrapping process, allowing you to set up different wrap sequences, layer patterns, top of pallet coverage, and speed controls. The intuitive interface simplifies the setup and adjustment process, ensuring maximum precision and flexibility.

This machine is specifically tailored for lighter-duty wrapping applications, where it can efficiently handle a volume of 10-30 standard-size pallets per day. Its robust construction and reliable components ensure durability and consistent performance, making it an ideal choice for businesses with moderate wrapping needs.

In addition to its advanced control capabilities, our pallet wrapping machine boasts an array of features designed to optimize your wrapping process. Equipped with stretch wrappers, it ensures optimal film usage by stretching the wrapping material, providing enhanced load stability and reducing material costs. Say goodbye to unnecessary waste and hello to increased efficiency and cost savings.

We understand that every business has unique packaging requirements. That’s why our pallet wrapping machine offers the flexibility to adjust wrap sequences, layer patterns, and top-of-pallet coverage, allowing you to customize the wrapping process to suit your specific needs. Whether you need to wrap irregularly shaped pallets or fragile goods that require extra protection, our machine can be tailored to meet your demands.

Investing in our advanced pallet wrapping machine will undoubtedly enhance your packaging efficiency and improve overall productivity. With its user-friendly interface and versatile features, it provides a reliable and automated solution that eliminates the need for manual labor-intensive wrapping.

Experience the benefits of our advanced pallet wrapping machine with a built-in PLC HMI display and take your packaging process to new heights. Contact us today to discuss your requirements and discover how our innovative solution can revolutionize your wrapping operations.CONTROL FEATURES

- PLC (Programmable Logic Control)

- Full color 4” touchscreen display

- (providing function control viewing)

- 1/2 HP DC motors

- Variable Turntable Speed 0-15 RPM

- Variable Film Carriage Speed Up/Down Control

- Separate Top/Bottom Wrap Selectors 1-9

- Separate Film Height Selector 1-9″

- Flush Mounted Control Panel (built into the tower)

- Cycle Counter

- Manual Carriage Raise/Lower Control

- Turntable Jog with Auto Home Alignment

- Large Emergency push button power On/Off switch with indicator light

- Start Cycle Push Button

- All circuits are protected by fuses (easy access)

FILM DELIVERY SYSTEM

- HURRICANE THREAD© 20″ prestretch film delivery system

- 200% factory set film stretch (50%-250% available upon request)

- Easy thread film carriage

- Electronic film force control on the panel

- Adjustable mechanical force to load

- Linear analog proximity sensor film feed speed control

- 1/2HP DC MOTOR variable speed film drive

- Triple beam auto height eye capable of recognizing all colors including black

CARRIAGE LIFT

- UHMW supports providing effortless movement and maximum stability (Qty4)

- Heavy duty ANSI #50 chain carriage lift

- 1/2HP DC MOTOR variable speed drive 60:1 GEARBOX

- The carriage chain is fully guarded

TURNTABLE DRIVE

- 0–15 RPM Table Speed

- 1/2HP DC MOTOR variable speed drive 20:1 GEARBOX

- Adjustable electronic soft start/stop

- Positive home position alignment

- Safety E-Stop button

- 36 table support wheels

- Portable from the front or back

FPS 200 SPECIFICATIONS:

PRODUCTION SPEED:

- 1-40 LPH*

LOAD SIZE

- 55″L x 55″W x 90″H (80″ Diagonal)

WEIGHT CAPACITY

- 5000LBS

STRUCTURAL

- WELDED STEEL CONSTRUCTION

TURNTABLE DRIVE

- 1/2HP DC MOTOR, 20:1 GEARBOX

- 36 BEARING TABLE SUPPORTS

TURNTABLE SPEED

- 0-15RPM

CARRIAGE DRIVE

- #50 ANSI CHAIN 60:1 GEARBOX

FILM DELIVERY

- HURRICANE PRESTRETCH CARRIAGE

FILM ROLL

- 20″ MACHINE FILM, 3″ CORE

POWER REQUIREMENTS

- 115VAC, 15A, 60Hz- PLUG AND PLAY

ONBOARD PROGRAMS

- STANDARD WRAP CYCLE

OPTIONS

- LOADING RAMP

- COMBINATION RAMP – FOR POWERED HAND TRUCKS

*Loads Per Hour- This may vary depending on load sizes, loading/unloading speeds, and the number of wraps or wrapping pauses on load.